In the fast-evolving world of electronics and intelligent systems, embedded hardware design is the backbone of innovation. From medical devices and smart appliances to automotive control units and industrial automation, embedded systems power our daily lives. At the heart of a successful embedded hardware design process lies prototype development—a critical phase that bridges the gap between conceptual ideas and market-ready products.

Understanding and implementing robust prototype development practices is essential for companies like Monarch Innovation, which operate at the cutting edge of technology and product development. This blog explores the role of prototype development in embedded hardware design, its key benefits, methodologies, and how it contributes to reducing time-to-market while ensuring product quality.

What Is Embedded Hardware Design?

Embedded hardware design refers to the creation of dedicated computing systems integrated into larger devices. Unlike general-purpose computers, embedded systems are designed to perform specific tasks efficiently. They include components like microcontrollers, memory modules, sensors, power systems, and communication interfaces.

Designing such systems requires a deep understanding of both hardware and software components and how they interact in real-world scenarios. Given the complexity of these systems, errors in design can lead to high costs, delayed timelines, or product failure. That’s where prototype development comes into play.

Why Prototype Development Matters

Prototyping is the process of creating a working model or sample of a product before full-scale manufacturing. In embedded hardware design, prototyping allows engineers to validate concepts, test functionality, identify issues, and gather user feedback all before committing to mass production.

1. Validating Design Concepts

Embedded systems must meet precise technical specifications and operate in diverse environments. A prototype helps validate whether the proposed design architecture and component choices meet these requirements. It acts as a proof-of-concept, enabling the design team to test assumptions early in the development lifecycle.

2. Cost Efficiency

Catching errors during the prototyping stage is far more cost-effective than post-production fixes. Reworking a physical prototype is relatively inexpensive compared to the financial loss of faulty mass-produced hardware.

3. Identifying Design Flaws

Even the most thorough design plans can harbour unexpected flaws. Prototypes allow engineers to test the actual hardware under simulated or real-world conditions, uncovering design issues that may not surface in digital simulations.

4. Improved Communication and Collaboration

A physical prototype offers a tangible reference point for stakeholders, including engineers, designers, project managers, and clients. It helps foster clearer communication and better alignment with goals and expectations.

5. Faster Time-to-Market

By using iterative prototyping, teams can refine their designs quickly, reducing development time. Prototypes enable rapid experimentation, which leads to faster decision-making and accelerates the overall product development timeline.

Stages of Prototype Development in Embedded Hardware Design

At Monarch Innovation, the prototyping process is tailored to align with client needs and project scope. However, the general stages include:

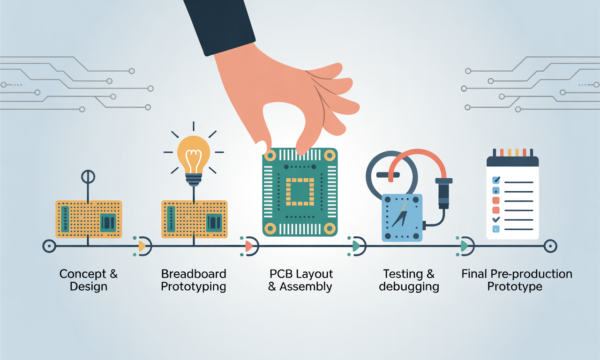

1. Conceptual Design & Block Diagram

This stage involves defining the system’s core functionality, requirements, and block-level architecture. It includes selecting key components such as microcontrollers, memory, I/O interfaces, and power management systems.

2. PCB Layout and Fabrication

Once the schematic is finalized, it’s translated into a PCB (Printed Circuit Board) layout. The design team determines optimal component placement and routing to ensure signal integrity and manufacturability. This layout is then used to fabricate the prototype board.

3. Schematic Design & Simulation

Electrical schematics are created to detail component connections. Simulation tools help verify logical operations, voltage levels, and signal timing. At this point, the design exists only in a virtual environment.

4. Assembly & Hardware Bring-Up

The fabricated PCB is populated with components (either manually or through automated assembly). Engineers then power up the board for the first time—a process known as “bring-up”—to test basic functionality and verify that the board doesn’t exhibit hardware faults.

5. Firmware Development and Integration

Embedded systems rely heavily on firmware. During this phase, the team writes low-level code and flashes it into the microcontroller to control hardware operations. They test communication protocols, sensor integrations, and real-time functionalities.

6. Testing and Debugging

The team thoroughly tests the hardware under real or simulated conditions. Engineers use tools like oscilloscopes, logic analyzers, and emulators to monitor signal behavior, timing issues, and performance metrics.

7. Iteration and Optimization

Based on test results, the team may revise and improve the prototype multiple times, swap components, adjust layouts, and optimize power consumption. This iterative refinement ensures the final design is robust and production-ready.

Tools and Technologies Used in Prototyping

Modern embedded hardware prototyping relies on a wide array of advanced tools:

- CAD Software: Tools like Altium Designer, Eagle, and KiCad for schematic and PCB layout.

- Microcontroller Platforms: STM32, AVR, ESP32, and ARM-based processors.

- Prototyping Boards: Arduino, Raspberry Pi, and custom dev kits for rapid testing.

- Simulation Tools: SPICE simulators and system modelling tools.

- Testing Equipment: Multimeters, oscilloscopes, logic analyzers, and JTAG debuggers.

Monarch Innovation’s expertise lies in integrating these tools seamlessly into client workflows, ensuring efficient and high-quality prototype development.

Prototyping for Innovation and Customization

Embedded systems often require customization depending on the industry. For example:

- Automotive applications demand high-reliability ECUs and real-time processing.

- Consumer electronics require power-efficient, user-friendly interfaces.

- Healthcare devices must meet strict regulatory standards for safety.

Consequently, prototyping enables design teams to tailor the hardware to meet these specific requirements, ensuring compliance, performance, and user satisfaction.

Monarch Innovation’s Approach

At Monarch Innovation, prototype development is not just a technical phase—it’s a strategic process. The company collaborates closely with clients to:

- Translate concepts into working prototypes

- Optimise hardware for cost, power, and performance

- Prepare for a smooth transition into mass production

- Reduce design risks through thorough testing

Whether developing IoT devices, medical equipment, or industrial control systems, Monarch Innovation’s end-to-end prototyping services play a vital role in bringing innovative ideas to life.

Conclusion

In today’s competitive landscape, prototype development is indispensable in embedded hardware design. It accelerates innovation, ensures reliability, and minimises costly errors. Companies that invest in high-quality prototyping not only speed up product development but also gain a significant edge in the marketplace.

Monarch Innovation continues to lead the way by combining technical excellence with a client-focused approach, transforming embedded system concepts into powerful, real-world solutions.