Rapid Prototyping Services

Online Rapid Prototyping Services

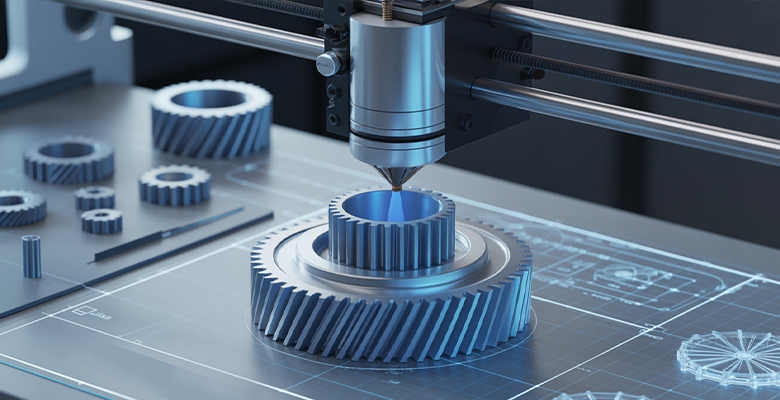

Monarch Innovation offers cutting-edge rapid prototyping services to bring product concepts to life swiftly. Our advanced techniques, including 3D printing, CNC machining, and injection molding, allow for quick iteration and testing of prototypes before full-scale production. We help businesses reduce development cycles, minimize costs, and enhance product performance with precise, high-quality prototypes. Our expertise spans various industries, ensuring tailored solutions that meet specific requirements. Whether you need a functional prototype or a visual model, our team delivers innovative solutions to accelerate your product’s journey to the market.

Additive Manufacturing Services

Additive Manufacturing (AM), or 3D printing, is a cutting-edge production process that builds objects layer by layer from digital designs, enabling complex geometries with minimal material waste. Unlike traditional subtractive methods, AM enhances efficiency, customization, and design flexibility across industries like aerospace, automotive, and healthcare. Using advanced technologies such as SLA, SLS, and FDM, it accelerates production, reduces lead times, and optimizes performance, making it a game-changer for modern manufacturing.

At Monarch Innovation, we leverage cutting-edge 3D printing services to transform ideas into tangible models. Our services encompass rapid prototyping, functional parts production, and customised manufacturing using high-quality materials such as resin, metal, and thermoplastics. With expertise in FDM, SLA, and SLS printing methods, we provide cost-effective and precise solutions for diverse industries.

We provide advanced metal 3D printing services using DMLS and SLM technologies, delivering high-strength, precise components for aerospace, automotive, and medical industries. Our process reduces waste, accelerates production, and enables innovative designs for complex, high-performance applications.

Monarch Innovation offers plastic 3D printing services for prototyping and end-use parts using FDM, SLA, and SLS technologies. We provide high-quality, lightweight components in ABS, PLA, nylon, and resin, ensuring precision, affordability, and fast turnaround. Ideal for engineers and designers, our services enable rapid iteration and customisation.

Rapid Design Manufacturing Services

We provide advanced rapid manufacturing solutions tailored to the evolving needs of modern industries. Our expertise spans precision machining, automation, additive manufacturing, and high-performance material processing. By leveraging cutting-edge technology and engineering excellence, we enhance efficiency, reduce costs, and improve product reliability for industries like aerospace, automotive, and medical devices.

Monarch Innovation specializes in precision CNC machining, offering advanced milling, turning, and multi-axis capabilities for high-accuracy metal and plastic parts. With strict quality control, we ensure superior finishes and dimensional accuracy, serving industries like aerospace, medical, and industrial equipment for both prototyping and large-scale production.

Industries We Serve

Architecture

Automation

Electronic

Connect with us for all your Engineering design needs

Address

3rd Floor, Dwarkesh Business Hub,

Opp.Home Town, Motera,

Ahmedabad-380005, GJ, India