Metal heat treatment is one of the most essential processes in manufacturing, engineering, and product design. By carefully heating and cooling metals under controlled conditions, industries can significantly improve mechanical strength, durability, hardness, and resistance to wear. Dependency on the correct heat treatment process will help achieve the components required to operate as needed, whether in the production of precision parts within the aerospace, automotive, or machinery tooling world.

This blog addresses the reasons to settle on the correct heat treatment services and the main metal heat treatment methods, applications, and uses. We shall also point out how current businesses are combining rapid prototyping services with heat treatment as a way of speeding up innovation processes.

What is Metal Heat Treatment?

Heat treatment or metallic heat treatment is a well-controlled process in which metals are heated and cooled in order to alter their physical and mechanical properties, albeit without changing their shape.

Prime goals of heat treatment are:

- Increasing strength and hardness

- Enhancing the ductility and toughness

- Increase in resistance to wear and corrosion

- Decreasing the internal stresses

- Better machinability and formability

In the case of industries, the determination of the applicable types of techniques in heat treatment can be determined by the kind of performance required in the material and the application required.

Why is the Heat Treatment Significant?

Before unfolding the various techniques, a sense of purpose is needed regarding why heat treatment is indispensable to modern manufacturing:

1. Better Performance: Metals well-treated withstand high stress, and they also work better in harsh conditions.

2. Cost Efficiency: The tool life can be maximised, lowering wear and heating during heat treatment, thus cutting on replacement costs.

3. Customisation: Engineers can tune material characteristics to suit the requirements of a project.

4. Safety: Heat-treated parts reduce risks of structural failures, ensuring safer end-use applications.

In short, the uses of heat treatment extend far beyond durability—they directly impact efficiency, safety, and innovation.

Common Metal Heat Treatment Techniques

1. Annealing

The metal is raised to some temperature and then cooled slowly, usually in a disagreement.

Purpose:

- Relieves internal stresses

- Softens the metal for improved machinability

- Refines grain structure for uniformity

Applications:

- Common in sheet metal, wires, and automotive components

- Used where ductility and flexibility are more important than hardness

2. Normalising

Normalising heats the metal above its critical temperature and allows it to cool in air. Unlike annealing, cooling here is faster.

Purpose:

- Improves toughness

- Produces uniform grain structure

- Enhances machinability compared to untreated steel

Applications:

- Structural steel components

- Automotive parts

- Machinery shafts and gears

3. Hardening

Hardening involves heating steel to a high temperature and rapidly cooling (quenching) it in water, oil, or brine.

Purpose:

- Increases hardness and strength

- Reduces wear and deformation under load

Applications:

- Cutting tools

- Bearings

- Dies and punches

4. Tempering

Tempering follows hardening. It heats and re-cools the hardened steel to a lesser temperature.

Purpose:

- Reduces brittleness caused by hardening

- Increases toughness while retaining strength

Applications:

- Springs

- Blades

- Automotive components require both strength and flexibility

5. Case Hardening (Surface Hardening)

Case hardening strengthens only the outer surface of the metal while keeping the core relatively soft and ductile.

Purpose:

- Improves surface wear resistance

- Retains core toughness to absorb shocks

Applications:

- Gears

- Shafts

- Camshafts and crankshafts

6. Quenching

Quenching refers to a metal that is cooled very fast in order to harden it after heating it.

Purpose:

- Achieves maximum hardness and strength

- Enhances durability in heavy-duty applications

Applications:

- Cutting blades

- Industrial dies

- Military-grade hardware

7. Stress Relieving

This technique involves heating metals to a moderate temperature below the transformation point and cooling gradually.

Purpose:

- Relieves internal stresses from welding, machining, or casting

- Prevents distortion and cracking during service

Applications:

- Welded structures

- Pressure vessels

- Large fabricated components

Comparing Different Heat Treatment Techniques

| Technique | Key Benefit | Main Use Case |

| Annealing | Softness, ductility | Sheet metal, wires |

| Normalizing | Toughness, grain uniformity | Structural steel, shafts |

| Hardening | Maximum hardness | Tools, dies, bearings |

| Tempering | Toughness with strength | Springs, blades |

| Case Hardening | Hard surface, tough core | Gears, shafts |

| Quenching | High strength, wear resistance | Blades, heavy-duty parts |

| Stress Relieving | Stability, reduced distortion | Welded and machined components |

Uses of Heat Treatment in Different Industries

Heat treatment is not limited to metallurgy alone. Its scope covers a wide range of industries:

- Aerospace: Turbine blades, landing gear, and aircraft frames of high strength.

- Automotive: Transmission parts, transmission systems, suspension parts.

- Medical Devices: Surgery, implants, and prosthetics that have to be precise.

- Manufacturing: machine tools, moulds, and dies.

- Reinforced structural steel can be used in the construction of bridges or skyscrapers.

Each of the applications demands a unique style of heat treatment method, making the case for specialised heat treatment services critical.

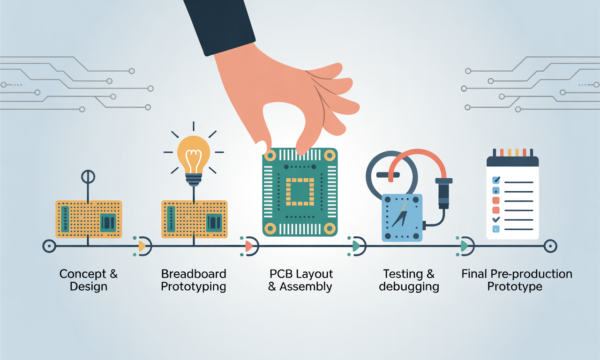

The Role of Heat Treatment in Rapid Prototyping

- Heat treatment: The purpose of heat treatment is to ensure that prototype parts are as strong and resistant to wear as the end product.

- Material Simulation: Engineers can simulate the real-life conditions to perfect the designs before engaging in large-scale production.

- Custom Properties: Through special treatments, prototypes can be adapted to special needs, like flexibility, hardness, or toughness.

Integrating rapid prototyping with effective heat treatment enables businesses to cut down on time-to-market, but at the same time coming up with highly revolutionary and long-lasting designs.

Selecting the Most Appropriate Heat Treatment Services

It is essential to choose the appropriate partner for the heat treatment services. Here is what to consider:

- The skills of various methods (annealing, hardening, tempering, case hardening, etc.)

- Aerospace, automotive, or medical component industry experience

- Some degree of quality control and precision is required to have repeatable results

- Includes integration with rapid prototyping services to support faster product cycles

Monarch Innovation: Your Partner in Heat Treatment and Prototyping

At Monarch Innovation, we understand that precision and performance are non-negotiable in today’s competitive markets. Our metal heat treatment services are designed to help industries unlock the full potential of their materials. By combining expertise in various heat treatment techniques with advanced rapid prototyping services, we deliver solutions that are both innovative and reliable.

Whether you manufacture an automotive part, enhance an aerospace component, or test one, Monarch Innovation will meet the best quality standards compliant with every single step. Our highly qualified specialists will work with clients to deliver custom solutions where the properties of the metal are precisely matched to the project’s requirements.

Go on to the next step with Monarch Innovation. We can assist you in optimising your designs, refining your materials, and driving any innovation process.

Frequently Asked Questions

1. What is metal heat treatment?

Metal heat treatment is the controlled heating and cooling of metals to change their microstructure and mechanical properties (hardness, strength, ductility, toughness) without altering composition. It’s used to tailor parts for specific service requirements.

2. Why is heat treatment important for steel and other alloys?

Heat treatment improves performance — e.g., increases hardness and wear resistance or restores ductility after forming — so parts last longer and perform reliably in safety-critical applications.

3. What are the most common metal heat treatment techniques?

The most common techniques are annealing, normalizing, quenching & tempering, case hardening (carburizing, nitriding), induction hardening, and precipitation (age) hardening. Each changes microstructure differently to meet design goals.

4. What is normalizing vs annealing — which to choose?

Normalizing uses faster cooling in air to produce a more uniform, fine-grained structure and is quicker than annealing. Choose normalizing for improved strength and machinability when annealing’s softening is not required.

5. Can heat treatment fix distorted parts or residual stresses?

Certain annealing and stress-relief cycles are specifically used to relieve residual stresses and reduce distortion; however, excessive distortion sometimes requires mechanical straightening plus controlled heat treatment.