When it comes to architectural projects, millwork shop drawings are the backbone of precision and quality. These drawings are more than just blueprints; they act as the roadmap to bring intricate designs to life. Millwork shop drawings are used to design and construct everything from custom cabinets to detailed paneling to complete every aspect possible. In this case, this blog will seek to discuss the seven aspects of millwork shop drawings following their relevance in architectural millwork projects.

Millwork Shop Drawings – The Essentials You Should Know

Millwork shop drawings are approved technical drawings that indicate how shop-fabricated elements of the millwork such as doors, cabinetry, molding, and trim will look physically when installed. These drawings mainly include construction drawings, which are usually specific to a project and afford a roadmap to manufacturers, contractors, and installers. Millwork shop drawings are not vague like general architectural drawings, or blueprints, as they concentrate on minor details to make each piece for installation fit the other.

1. Dimensional Accuracy

Historically, dimensional accuracy is considered to be the foundation on which any millwork shop drawing must be based. They also include dimensions that show that each part should be produced accurately to the correct dimensions. Dimensional details are essential for:

- Such errors result in increased costs of manufacturing and thus can be avoided.

- Maintaining a hassle-free installation.

- Consistency with the over-design objectives.

For example, when designing cabinetry, The shop drawings will show the height: width: in-depth: and clearances on the same. It is because of such details that millwork shop drawings are slightly different from conventional construction plans.

2. Material Specifications

Selecting certain materials can define whether the designed project will have good looks and utility. Millwork shop drawings specify the types of materials to be used, including:

- Wood Types: Those that are referred to as hardwoods like oak, maple, or walnut.

- Finishes: Paint, stains, or laminates.

- Hardware: Doors and door handles, drawers and knobs, and runners.

Such specifications are important so that everyone involved knows what the next steps will be, and to keep everything standardized throughout the project. Explicit descriptions of the materials are relevant most where high-end finishes or specific materials need to be used based on the design intent.

3. Joinery Details

The process of assembly or bringing different pieces together to create what is referred to as millwork is an essential component in the design process and one that has a direct bearing on the ability of the final structure to be durable and strong. Shop drawings include detailed illustrations of the joinery techniques to be used, such as:

- Drawer front rail and back rail joint, referred to as dovetail joints.

- Frames by mortise and tenon joints.

- Rabbet joints for paneling.

Providing these details in the drawings allows the fabricators to design and construct millwork pieces that are as strong, durable, and aesthetically appealing as the design intended.

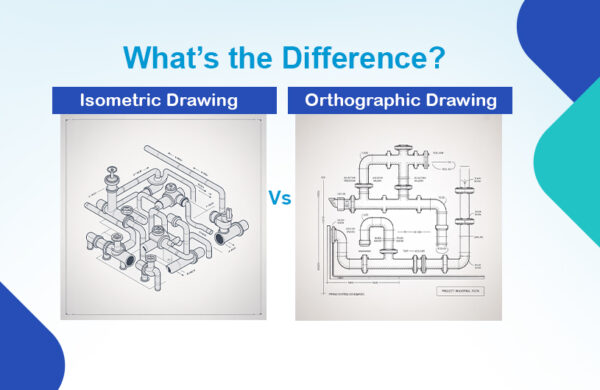

4. Types of Drawings

Millwork types of drawings consist of several categories of drawings to enable the client to have the best understanding of the project. Some of the key types include:

- Plan Views: Elevations which is the ideal view of the overall look as well as structural positioning of the millwork items.

- Elevations: Coordinate axis plans or vertical perspective which describe the height and other proportional characters.

- Sections: Vertical and horizontal sectional views that provide internal arrangement and construction techniques.

- Isometric Views: Prospective views that are overall better for visualizing the final plan.

Such drawings enable the relationship between an architect’s conceptual vision and a builder’s implementation to be easily understood and accomplished.

5. Compliance with Building Codes

Compliance with local building codes and regulations is non-negotiable in any architectural project. Millwork shop drawings include detailed notes and annotations to ensure that the designs meet all necessary standards. This includes:

- Fire safety regulations.

- Accessibility requirements.

- A list of guidelines to be followed by the structure shall include:

That way, none of these details will be a hindrance to the project or cause legal issues to arise.

6. Customization and Design Intent

Millwork can be a very specific design that is designed to meet the particular requirements of a certain area. Shop drawings have a very important function in realizing the architectural design concept. They include:

- Made-to-order trim and casing profiles.

- High customization of cabinetry designs.

- Extra parameters such as secret storage or built-in lighting.

Such drawings help achieve the architect’s dream as well as the client’s dream in the final design of the building.

7. Working in conjunction with Other Trades

Any form of architectural millwork cannot be standalone; it needs to harmonize with other parts of the structure, including plumbing, electricity, and HVAC. Millwork shop drawings include coordination notes to:

- With plumbing fixtures, it fits well to align it with cabinetry.

- Make adequate provision for outlets used for electrical appliances.

- Endeavor to meet mechanical air systems within millwork installations.

This coordination reduces clashes during the construction process, especially during the installation stage, and guarantees every tradesman to flow well throughout the construction phase.

Millwork vs Casework: What’s the Difference?

About this topic, one can hear a common question in architectural design: what is the difference between millwork vs casework? While they may seem similar, there are distinct differences:

- Millwork: Accomplishments for a specific design include paneling, trim, and specialty cabinetry crafted to precise measurements. Millwork is fully custom work and usually very detailed depending on how different a project is.

- Casework: Pre-made components are used in most standardized cabinetry and storage installations. Casework is less versatile and also less expensive in comparison to custom-made casework.

Understanding these differences between millwork and casework helps in selecting the right approach for your project.

The Role of an Engineering and Designing Company

An experienced engineering and designing company, like Monarch Innovation, plays a vital role in creating accurate and detailed millwork shop drawings. From design to construction, we emphasize carefully planning every step. We achieve this through our expertise in architectural millwork and providing millwork shop drawing services to various clients.

Why Monarch Innovation?

Our company Monarch Innovation ensures excellent execution of the design you envision. If you require precise plans for your millwork shop or an entire millwork design solution for your home or commercial spaces, we have you covered. Having practiced architectural millwork for many years allows us to respect measures, individuality, and regulations.

Our services include:

- Custom millwork shop drawing services tailored to your project.

- Coordination with architects, contractors, and other trades.

- Use of advanced software to create highly detailed drawings.

If you decide to work with Monarch Innovation, you do not only get what you pay for – they are a dedicated team full of passion and proficiency.

Conclusion

Architecture project millwork shop drawings, in fact, form part of the framework required for any architectural project. They guarantee accuracy, specificity, and synchronization and can make elaborate designs become real. These two-dimensional drawings enhance dimensional accuracy, specify materials, detail joinery methods, and outline legal requirements.

If you’re looking for reliable millwork shop drawing services, Monarch Innovation is your go-to partner. Our expertise in architectural millwork and commitment to quality ensures that your project is in the best hands. Contact us today to learn more about how we can help bring your vision to life.