Rapid prototyping is the secret sauce behind today’s lightning-fast product development. Whether you’re a startup founder dreaming of the next great gadget or an engineer at a Fortune 500 company, the ability to quickly create functional prototypes is non-negotiable.

But here’s the big question: Should you use CNC machining or 3D printing to bring your ideas to life? Let’s break it down.

What is CNC Machining?

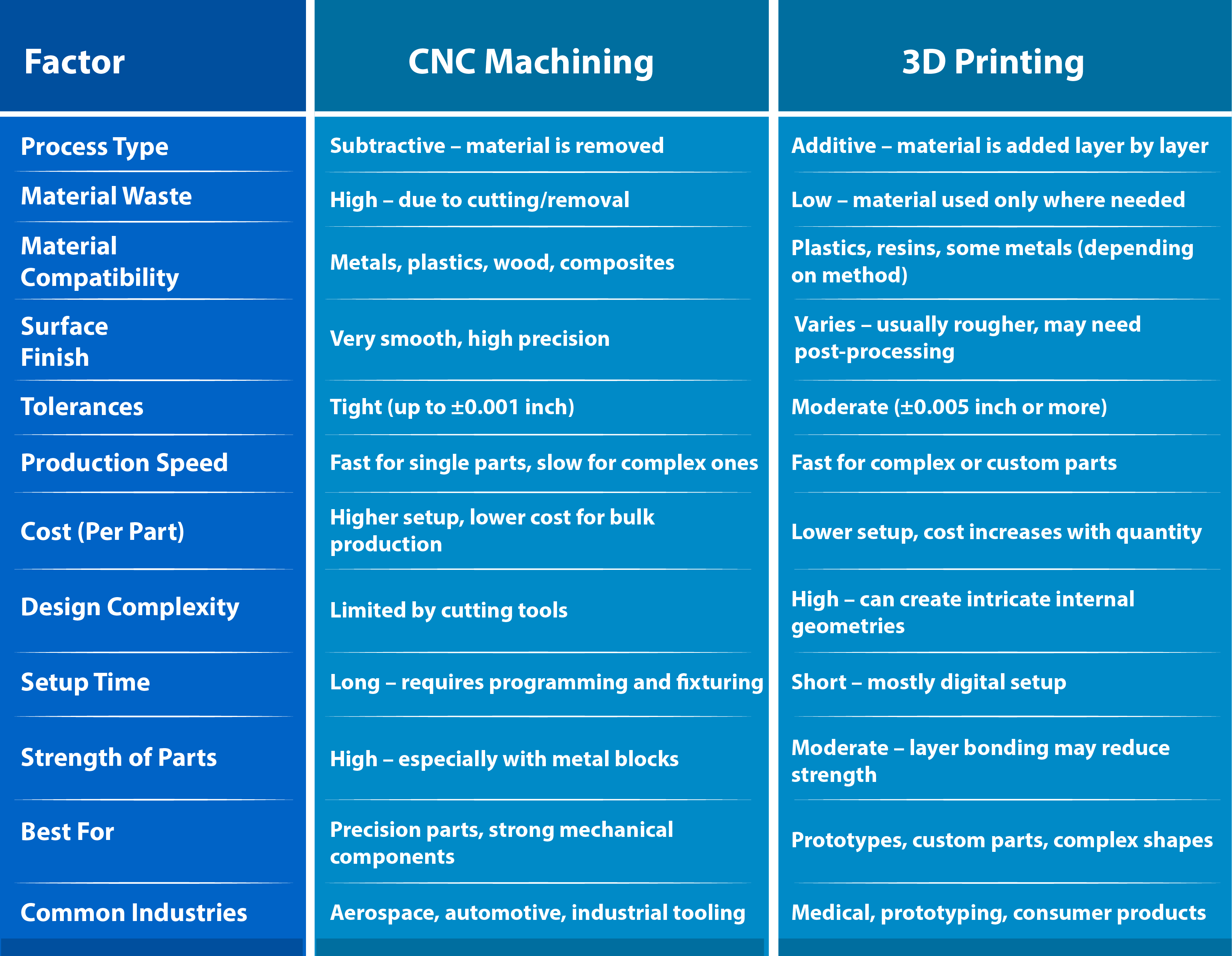

CNC (Computer Numerical Control) machining refers to a subtractive production process. It starts with a piece of material, metal, plastic or composite having a solid block, which is then removed by precision instruments to form the final part.

Important Characteristics of CNC Machining:

- High Precision: Tolerances down to: -0.005 mm

- Versatility: Can work with metals, plastics, or high-performance composites

- Surface Finish: Excellent finish quality, suitable for functional testing

- Scalability: Can be easily scaled between the prototype and the production environment

Types of CNC Machines Used for Prototyping

- CNC Mills

- CNC Lathes

- CNC Routers

- Multi-axis Machines

What Is 3D Printing?

This is what 3D printing (or additive manufacturing) does: layer-by-layer parts are built using thermoplastics, resins and/or metal powders. It begins with a digital 3D model, and it does not need tooling; thus, it is extremely low cost per complex design and early-stage prototyping.

Characteristics of 3D Printing:

- Configurability: Allows complex geometries and interior passages

- Low Up Front: No tooling and moulds necessary

- Material: Limited mostly to resins and plastics

Common 3D Printing Technologies

- FDM (Fused Deposition Modelling)

- SLA (Stereolithography)

- SLS (Selective Laser Sintering)

- DMLS (Direct Metal Laser Sintering)

CNC Machining vs. 3D Printing: Core Process Differences

When to Choose CNC Machining for Rapid Prototyping

Opt for a CNC machining service if your prototype demands:

- Micro tolerance and stiffness

- Objects that do not work with 3D printing (e.g. aluminium, stainless steel)

- Instant changeover to the same process production

- Stress test/ thermal resistance

CNC machining best suits engineering-grade parts that have to be precise in meeting production requirements.

At What Stage to Select 3D printing Rapid Prototyping

3D printing service would be preferred if:

- You are at the design stage, and you want rapid, inexpensive prototyping

- Internal geometries are involved, which are complex

- The strength and the finish of the material are not of concern at the prototype stage

- You are doing form, fit or simple functionality testing You are doing form, fit or simple functionality testing

It glows where there is a high priority placed on speed and flexibility of design, and the vital consideration of longevity or precision is less significant.

Final Verdict: CNC Machining vs. 3D Printing

Both CNC Machining vs. 3D Printing have their advantages and disadvantages. CNC machining can be precise, but 3D printing is a much easier process and has flexibility. But, CNC machining is not as complicated as 3D printing, but it is more restricted somehow.

It does not have a unique size that fits all answers. Companies are, in fact, in most cases using both at various phases of the product development life-cycle by starting with 3D printing to validate their concepts and then flowing into CNC machining to actually test functionality and perform pre-production runs.

Select the Proper Partner in Rapid Prototyping

And regardless of whether you require a high precision CNC Machining service or a fast 3D printed prototype, the capabilities of your prototyping partner make the difference whether your project is a success or not.

At Monarch Innovation, we enable companies to develop their ideas into reality using professional (expert) level services such as CNC machining, thus 3D printing. As a complete solution Rapid Prototyping company, we have got it all going on… well, almost, we are experts in all areas of product development journey success, providing speed, accuracy and unmatched technical know-how.

Ready to accelerate your product development?

Contact Monarch Innovation, the best Rapid Prototyping company today, to discuss your prototyping needs with our experts.