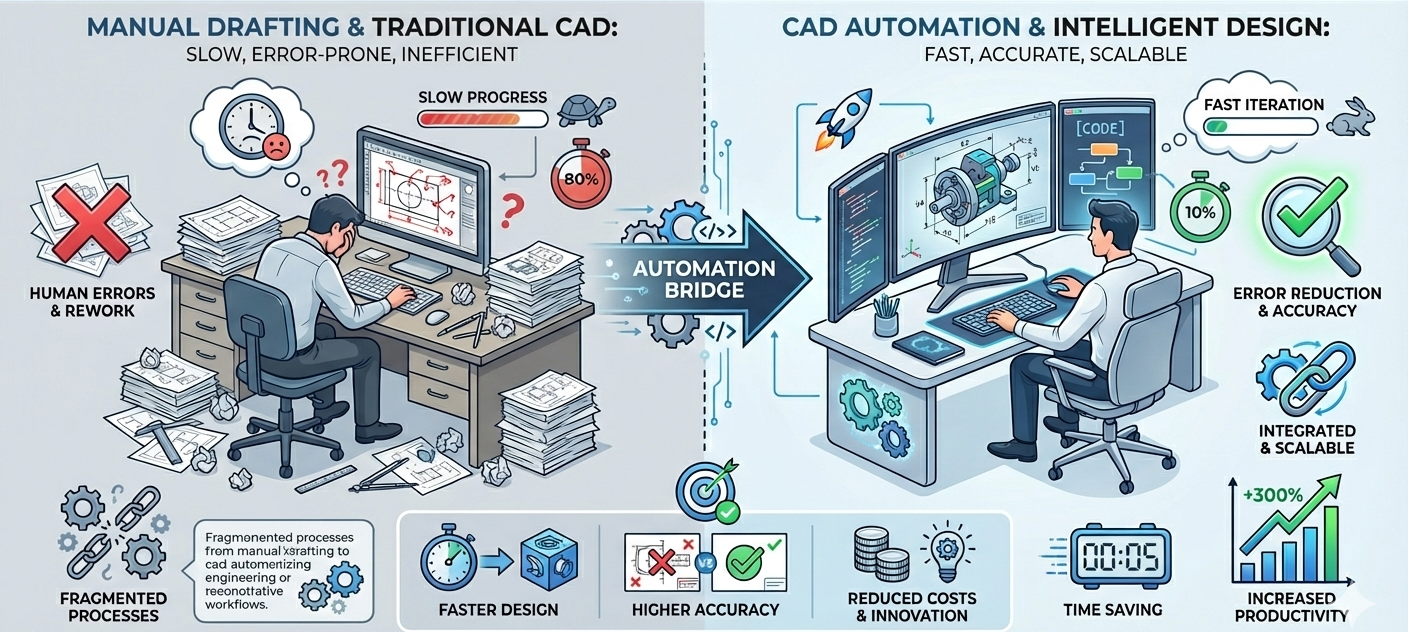

CAD automation for engineers uses rule-based modelling, scripts, and parametric design to reduce repetitive tasks, improve accuracy, and accelerate product development. It helps engineering teams save time, minimize errors, and scale designs efficiently across projects.

What Is CAD Automation?

CAD automation is the process of using predefined rules, scripts, and intelligent templates within CAD software to automatically create, modify, or validate engineering designs. Instead of manually drafting similar components, engineers can generate models and drawings instantly by changing parameters.

This approach is widely used in mechanical, manufacturing, automotive, and product design engineering to improve productivity and consistency.

Why CAD Automation Matters for Engineers

Engineering teams face tight deadlines, frequent design revisions, and increasing product complexity. CAD automation addresses these challenges by streamlining workflows and eliminating repetitive manual work.

Key Benefits of CAD Automation

- Faster design creation and updates

- Reduced human errors and rework

- Consistent design standards

- Improved collaboration between teams

- Scalable and reusable design systems

How CAD Automation Increases Engineering Efficiency

1. Eliminates Repetitive Design Work

Many engineering projects involve similar parts, assemblies, or layouts. CAD automation allows engineers to reuse intelligent templates instead of starting from scratch every time.

2. Improves Accuracy and Design Quality

Automated CAD models follow predefined rules and constraints, reducing dimensioning errors and ensuring compliance with design standards.

3. Speeds Up Design Changes

When design parameters change, automated models update instantly. This significantly reduces turnaround time during prototyping and client revisions.

4. Supports CAD Customization and Design

Through CAD customization and design, automation can be tailored to specific industry needs, workflows, and product requirements, making engineering processes more flexible and efficient.

5. Simplifies CAD Conversion and Migration

CAD automation plays a critical role in CAD conversion and migration, enabling faster and more accurate transfer of legacy data between CAD platforms while preserving design intent.

Common Use Cases of CAD Automation

- Parametric part and assembly generation

- Automated 2D drawings from 3D models

- Rule-based product configuration

- Design validation and compliance checks

- CAD conversion and migration projects

Why Engineering Teams Choose Monarch Innovation

Monarch Innovation helps engineering teams implement advanced CAD automation strategies that improve productivity and reduce operational costs.

By combining CAD customization and design with seamless CAD conversion and migration, Monarch Innovation enables businesses to modernize their design workflows without disrupting ongoing operations.

Is CAD Automation the Future of Engineering?

Yes. As product complexity increases and time-to-market becomes critical, CAD automation is no longer optional. Engineering teams that adopt automation gain a competitive advantage through faster delivery, better accuracy, and scalable design systems.

Conclusion

CAD automation for engineers transforms how design teams work by improving speed, accuracy, and scalability. With expert support from Monarch Innovation, businesses can leverage CAD customization, design automation, and seamless CAD migration to stay ahead in modern engineering environments.

FAQs

1. What is the main purpose of CAD automation?

The main purpose of CAD automation is to reduce manual effort, improve design accuracy, and speed up engineering workflows.

2. Does CAD automation replace engineers?

No. CAD automation supports engineers by handling repetitive tasks, allowing them to focus on innovation, problem-solving, and complex design decisions.

3. Can CAD automation help with CAD migration projects?

Yes. CAD automation significantly improves CAD conversion and migration by ensuring accurate data transfer and reducing manual rework.