Product Engineering Services are end-to-end solutions that cover the design, development, testing, and lifecycle management of a product. These services help businesses transform ideas into market-ready products by combining engineering expertise, digital technologies, and innovation.

What are Product Engineering Services?

It refers to the complete process of turning an idea into a functional, user-friendly, and competitive product. This includes:

- Product ideation and conceptualisation

- Design and prototyping

- Development and testing

- Manufacturing support

- Product lifecycle management

In short, product engineering ensures that businesses build the right product at the right time while staying cost-efficient and innovative.

Why Businesses Need Product Engineering Solutions

Companies face challenges like:

- Rapidly changing customer demands

- Shorter product lifecycles

- Intense global competition

- Faster innovation requirements

- Digital transformation needs

Product engineering services address these by:

- Speeding up time-to-market

- Reducing design and development costs

- Enhancing product quality and scalability

- Creating user-focused, future-ready solutions

Core Stages of Product Engineering and Development

1. Ideation & Conceptualisation – Identifying market needs and creating viable concepts.

2. Product Design – Industrial, mechanical, electronic, and software design.

3. Product Development – Prototyping, embedded systems, IoT/AI integration.

4. Testing & Validation – Ensuring safety, compliance, and usability.

5. Manufacturing Support – Supply chain setup and scalability planning.

6. Lifecycle Management – Continuous upgrades and improvements.

Key Benefits for Businesses

Businesses gain:

- Faster innovation

- Cost savings through smart design

- Assured quality and compliance

- Scalability for future needs

- Customer satisfaction through usability

- Competitive advantage in the market

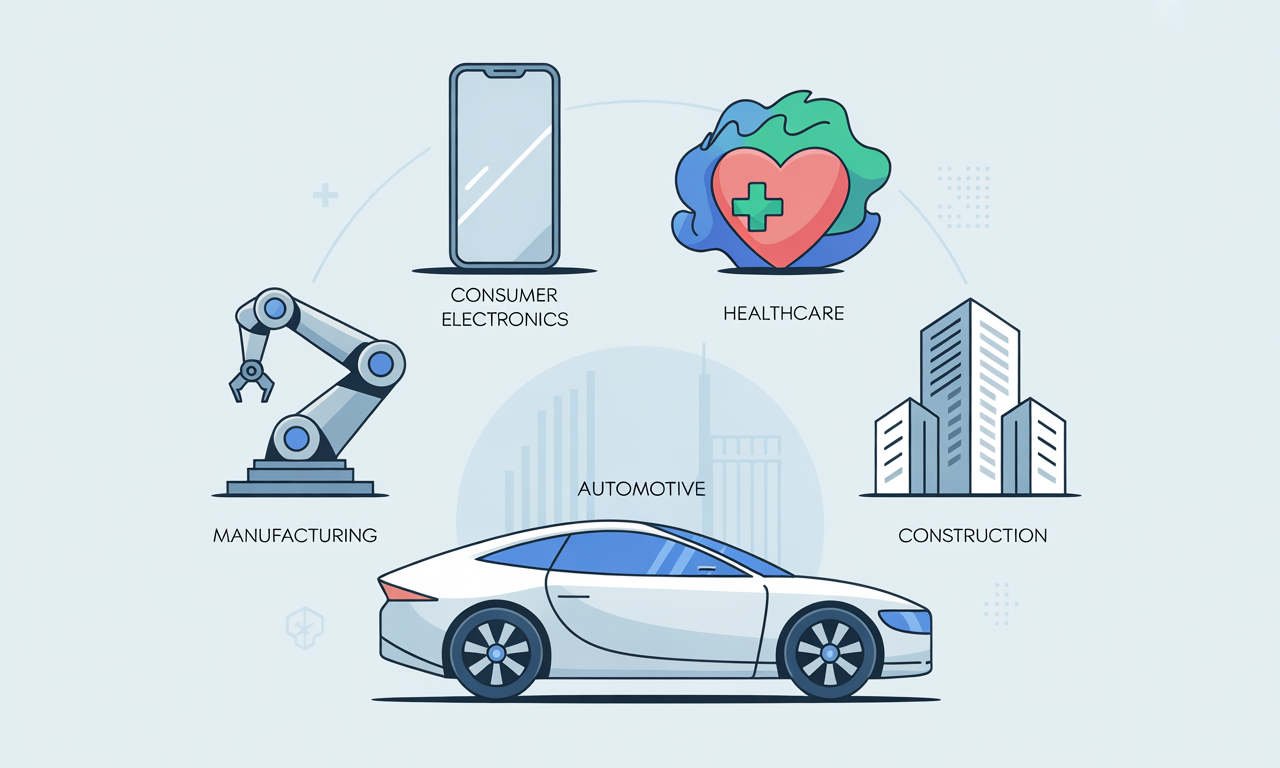

Industries Driving Innovation with Engineering Services

- Automotive – EVs, autonomous driving, connected cars

- Healthcare – Medical devices, wearables, telemedicine tools

- Consumer Electronics – Smartphones, IoT devices, home automation

- Manufacturing – Robotics, automation, smart factories

- Construction – Sustainable designs, digital innovations

The Future of Digital Product Innovation

The next wave of product engineering will be shaped by:

- AI-driven product design

- Digital twins for simulation

- Sustainable engineering

- 3D printing & mass customisation

- Cloud-based global collaboration

Product Engineering vs Traditional Engineering

| Aspect | Traditional Engineering | Product-Focused Engineering |

|---|---|---|

| Focus | Functionality only | Functionality + Market success |

| Process | Linear | Iterative & Agile |

| Innovation | Limited | Integrated with latest tech |

| Lifecycle | Ends at launch | Continuous improvements |

| User-Centric | Minimal | Strong focus |

This comparison shows why digital product engineering has become essential for modern businesses.

Why Choose Monarch Innovation?

At Monarch Innovation, we provide complete product engineering services tailored to your business needs. Our expertise includes:

- End-to-end product design and lifecycle support

- Deep industry experience (automotive, healthcare, manufacturing, electronics)

- Proficiency in AI, IoT, and automation

- Rapid, cost-effective, and scalable solutions

Final Thoughts

They are no longer a luxury- they are a necessity to any business that hopes to succeed in the current competitive markets. With the product design engineering services and the product development engineering services, the businesses can be able to innovate more quickly, offer more quality, and sustain customer loyalty in the long term.

The appropriate partner will not just assist you in designing and developing products; they will make sure that they are updated according to the requirements of the markets. That is where Monarch Innovation fits in- assisting companies to develop products that were and will be important today.

Frequently Asked Questions (FAQ)

1. What are product engineering services?

Product engineering services cover the entire lifecycle of a product—from idea and design to development, testing, and ongoing improvements. They help businesses create innovative, market-ready solutions that are cost-effective, scalable, and customer-focused.

2. Why do businesses need product engineering services?

Companies need product engineering services to reduce time-to-market, lower development costs, improve product quality, and stay competitive. These services enable businesses to respond quickly to customer demands and evolving market trends.

3. What is the difference between product engineering and traditional engineering?

Traditional engineering focuses mainly on functionality and ends after product launch. Product engineering is iterative, agile, and user-focused, covering design, development, testing, and continuous lifecycle management for long-term success.

4. What are the key stages of product engineering?

The main stages include ideation, product design, development, testing, manufacturing support, and lifecycle management. Each stage ensures the product meets customer expectations, industry standards, and business goals.

5. Which industries use product engineering services?

Industries like automotive, healthcare, consumer electronics, manufacturing, and construction rely heavily on product engineering services. These sectors need innovation, scalability, and digital solutions to stay relevant in competitive markets.