The world of computer-aided design (CAD) technology is constantly evolving, introducing innovative trends that shape the way we design and create. In this captivating blog series, we delve into the latest advancements in CAD including efficient CAD conversion methods, exploring the cutting-edge innovations that are propelling the industry forward. From software developments to hardware breakthroughs, we uncover the key elements that are reshaping the CAD landscape. Discover the power of parametric modeling, enabling dynamic and intelligent design iterations. Explore the realm of generative design, where algorithms and artificial intelligence drive creative exploration and optimization.

Witness the transformative impact of simulation and analysis capabilities, reducing reliance on physical prototypes. Immerse yourself in the world of virtual reality integration, revolutionizing design visualization and interaction. Experience the seamless collaboration facilitated by cloud-based CAD solutions, enhancing teamwork and project outcomes. Through real-world industry applications, such as automotive, aerospace, architecture, and consumer products, witness how CAD technology drives innovation and transforms sectors. Join us on this exhilarating journey as we unveil the latest trends and innovations in CAD technology, inspiring you to embrace the possibilities and shape the future of design.

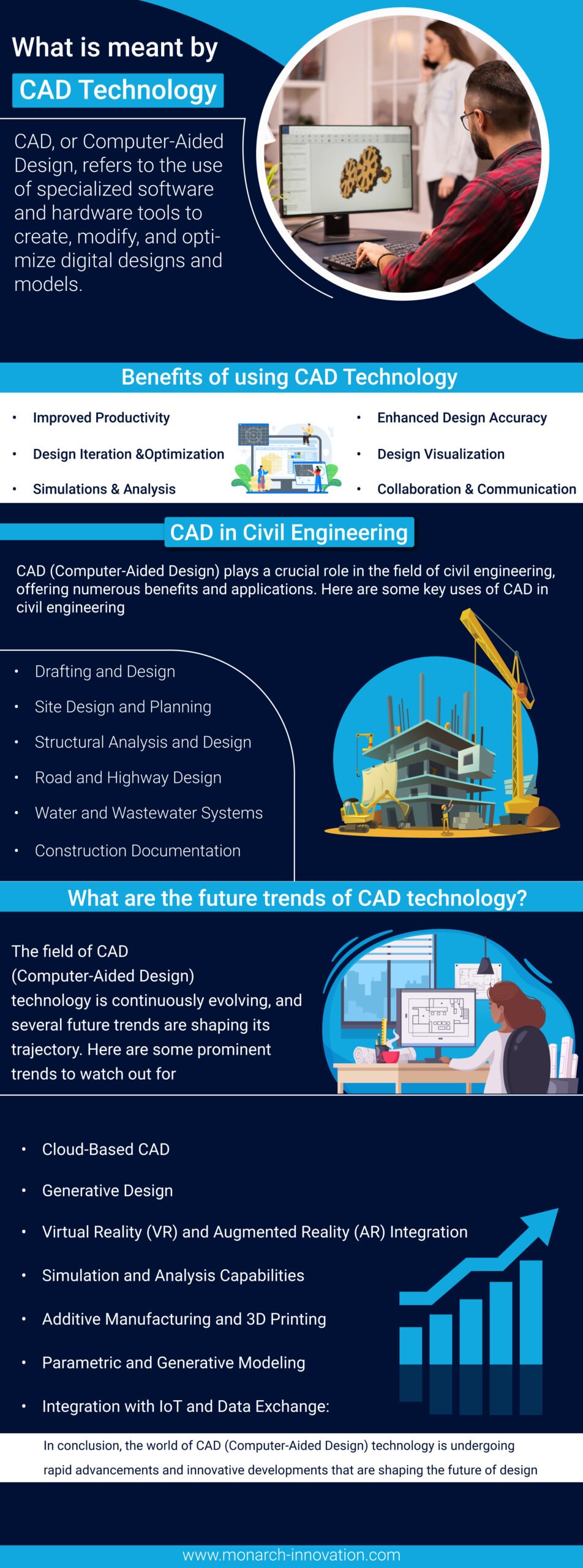

What is meant by CAD Technology?

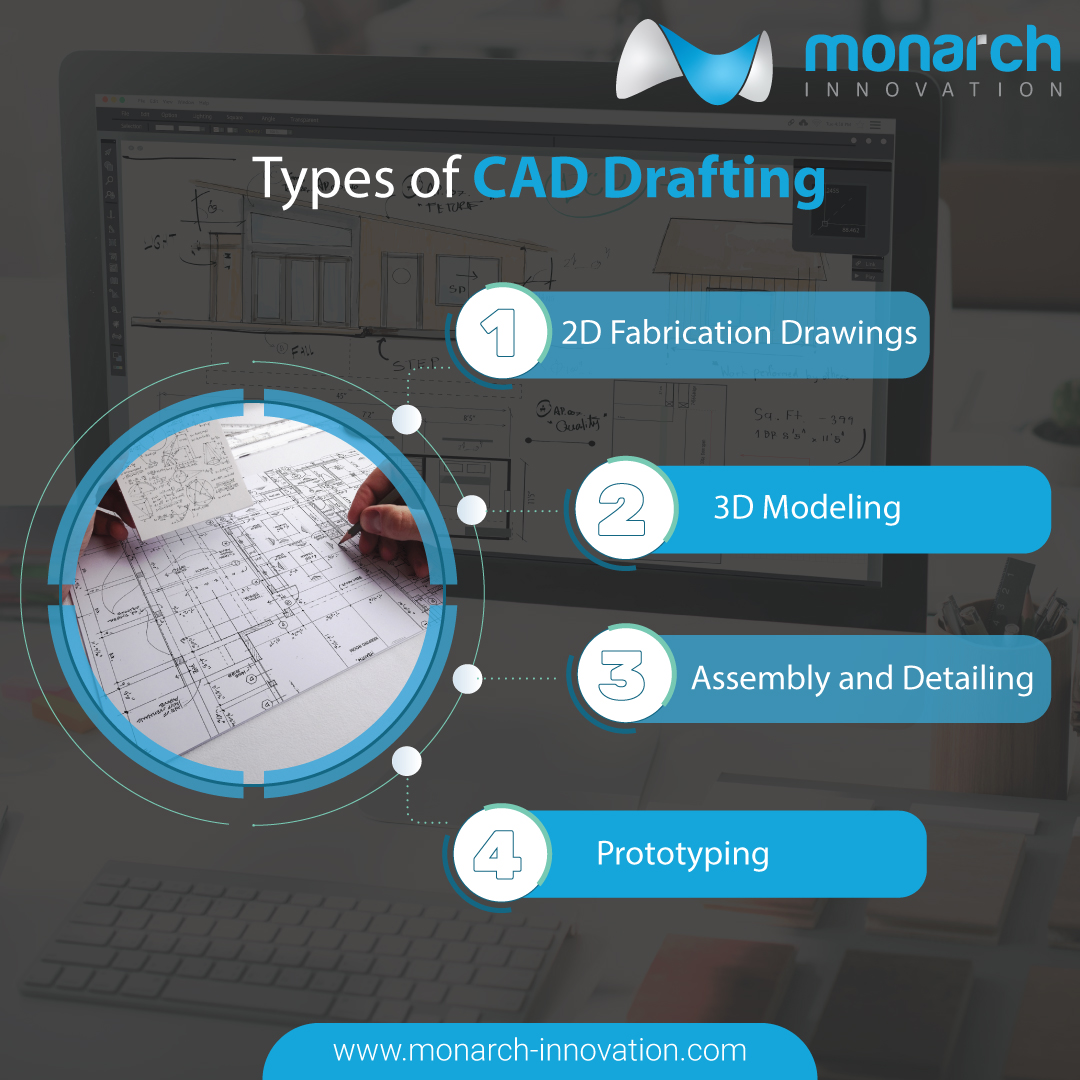

CAD, or Computer-Aided Design, refers to the use of specialized software and hardware tools to create, modify, and optimize digital designs and models. It is a technology that enables designers, engineers, and architects to design and visualize objects, structures, or systems in a virtual environment. CAD technology provides a wide range of capabilities, including 2D drafting, 3D modeling, parametric modeling, simulation, analysis, and documentation.

By leveraging CAD software, professionals can streamline the design process, improve accuracy, and enhance productivity. CAD technology has transformed industries such as engineering, architecture, manufacturing, and product design by enabling faster design iterations, precise measurements, efficient collaboration, and the ability to simulate real-world conditions. It has become an essential tool for creating and communicating complex designs, facilitating innovation, and bringing ideas to life in a digital realm.

Benefits of using CAD Technology

The use of CAD (Computer-Aided Design) technology offers numerous benefits across various industries and disciplines. Here are some of the key advantages:

- Improved Productivity: CAD tools provide efficient workflows, automation, and a wide range of design features that significantly increase productivity. Designers can create and modify designs more quickly and accurately compared to traditional manual methods, saving time and effort.

- Enhanced Design Accuracy: CAD technology enables precise and accurate design creation. Measurements, dimensions, and geometric relationships can be precisely defined and maintained, reducing errors, and ensuring design integrity.

- Design Visualization: CAD software allows designers to visualize their designs in 2D or 3D, providing a realistic representation of the final product or structure. This visualization aids in design analysis, evaluation, and communication with stakeholders, leading to better decision-making.

- Design Iteration and Optimization: CAD tools enable designers to easily iterate and refine designs. Changes can be made swiftly, and multiple design options can be explored, facilitating optimization and innovation. This iterative process helps to create more efficient and effective designs.

- Simulations and Analysis: CAD technology often includes simulation and analysis capabilities that allow designers to test and evaluate their designs virtually. These simulations can assess factors such as structural integrity, fluid dynamics, heat transfer, and more. By identifying and addressing design issues early in the process, costly physical prototyping and testing can be minimized.

- Collaboration and Communication: CAD software facilitates effective collaboration among team members, allowing them to work on the same design simultaneously and share design data seamlessly. This improves communication, reduces errors, and enhances coordination throughout the design process.

- Documentation and Manufacturing: CAD tools generate accurate and comprehensive design documentation, including drawings, specifications, and bills of materials. This information can be easily shared with manufacturers, ensuring precise replication of the design and minimizing production errors.

- Design Reusability and Maintenance: CAD technology enables the creation of design libraries and parametric models, making it easier to reuse and modify existing designs. This feature accelerates design iterations, simplifies maintenance, and promotes design standardization.

- Cost and Time Savings: By streamlining the design process, reducing errors, and enabling virtual testing, CAD technology helps to save costs and time associated with manual drafting, physical prototyping, and rework. It promotes efficiency and can expedite time-to-market for products.

Cad in civil engineering

CAD (Computer-Aided Design) plays a crucial role in the field of civil engineering, offering numerous benefits and applications. Here are some key uses of CAD in civil engineering:

- Drafting and Design: CAD software allows civil engineers to create accurate 2D and 3D drawings of structures, such as buildings, bridges, roads, and dams. It enables precise detailing of architectural elements, structural components, and infrastructure layouts.

- Site Design and Planning: CAD tools assist in site design and planning by providing tools for survey data integration, contour modeling, and land development. Civil engineers can create digital terrain models, analyze site conditions, and design grading plans more efficiently.

- Structural Analysis and Design: CAD software incorporates structural analysis capabilities that enable engineers to evaluate the strength, stability, and performance of buildings and infrastructure. It aids in designing structural elements, such as beams, columns, and foundations, while ensuring compliance with safety standards and regulations.

- Road and Highway Design: CAD technology facilitates the design of roads, highways, and transportation networks. Engineers can create alignments, cross-sections, and profiles, optimize road geometry, and analyze factors like traffic flow and safety.

- Water and Wastewater Systems: CAD tools assist in the design and modeling of water supply, drainage, and wastewater systems. Engineers can create pipe networks, hydraulic profiles, and stormwater management plans, ensuring efficient and sustainable water infrastructure.

- Construction Documentation: CAD software allows civil engineers to generate construction drawings, specifications, and quantity takeoffs. This documentation provides precise instructions for contractors, reducing errors during construction and enhancing project coordination.

- Visualization and Presentations: CAD technology enables realistic 3D visualizations and renderings of civil engineering projects. Engineers can create walkthroughs, flyovers, and virtual reality experiences to effectively communicate design concepts to clients, stakeholders, and regulatory bodies.

- BIM Integration: Building Information Modeling (BIM) is closely linked to CAD in civil engineering. BIM software utilizes CAD data to create intelligent, information-rich models that facilitate collaboration and coordination among different disciplines involved in a project, including architects, structural bim engineers, and MEP (Mechanical, Electrical, Plumbing) professionals.

- Project Collaboration and Management: CAD tools support collaborative work environments, allowing civil engineering teams to work concurrently on different aspects of a project. It promotes efficient communication, reduces conflicts, and streamlines project management processes.

CAD has transformed the civil engineering industry by providing powerful tools for design, analysis, documentation, and collaboration. It enhances efficiency, accuracy, and productivity while facilitating innovation in infrastructure development and construction projects.

What are the future trends of CAD technology?

The field of CAD (Computer-Aided Design) technology is continuously evolving, and several future trends are shaping its trajectory. Here are some prominent trends to watch out for:

- Cloud-Based CAD: Cloud computing is revolutionizing CAD, allowing users to access software and store data in the cloud. This trend enables real-time collaboration, seamless data sharing, and enhanced flexibility across multiple devices and locations.

- Generative Design: Generative design takes advantage of algorithms and artificial intelligence to explore numerous design iterations and find optimal solutions based on specified constraints. It enables designers to harness the power of computational algorithms to generate innovative and efficient designs.

- Virtual Reality (VR) and Augmented Reality (AR) Integration: CAD systems are increasingly incorporating AR and VR technologies, providing immersive experiences for design visualization and interaction. Designers can step into virtual environments, visualize their designs at scale, and make real-time modifications, enhancing the design review and validation process.

- Simulation and Analysis Capabilities: CAD tools are becoming more advanced in terms of simulation and analysis features. Integrated analysis modules allow engineers to perform virtual testing, predict performance under different conditions, and optimize designs early in the development process, reducing the need for physical prototypes.

- Additive Manufacturing and 3D Printing: CAD technology is closely intertwined with additive manufacturing and 3D printing processes. As these manufacturing methods continue to advance, CAD systems will incorporate specific tools and workflows for designing complex geometries and optimizing designs for additive manufacturing.

- Parametric and Generative Modeling: Parametric modeling, which allows the use of variables and relationships to create intelligent designs, will continue to evolve. Additionally, generative modeling, driven by AI algorithms, will offer designers new ways to explore and generate design options based on specific objectives and constraints.

- Integration with IoT and Data Exchange: CAD technology is expected to integrate more closely with the Internet of Things (IoT) systems and enable seamless data exchange between physical devices and digital models. This integration will streamline design processes, allow for real-time data-driven decisions, and facilitate the development of smart connected products and infrastructure.

- Artificial Intelligence and Machine Learning: AI and machine learning techniques will further enhance CAD capabilities, including automating repetitive design tasks, predicting design performance, and providing intelligent design recommendations based on historical data and user preferences.

- Enhanced User Experience: CAD software interfaces and workflows will continue to evolve, focusing on user-friendliness, intuitive design, and enhanced productivity. User-centric features such as gesture-based controls, natural language processing, and context-aware design tools will contribute to a more efficient and enjoyable CAD experience.

These trends reflect the ongoing advancements in CAD technology, driven by the demand for increased productivity, design innovation, collaboration, and the integration of emerging technologies. By staying abreast of these trends, professionals in the field can adapt and leverage the latest tools and capabilities to enhance their design workflows and stay at the forefront of the industry.

Conclusion

In conclusion, the world of CAD (Computer-Aided Design) technology is undergoing rapid advancements and innovative developments that are shaping the future of design. The trends discussed in this blog highlight the ongoing transformation and the immense potential of CAD in various industries. Embracing these trends and staying abreast of the latest developments will be crucial for individuals and organizations to thrive in this dynamic and ever-evolving landscape of CAD technology. Contact Monarch Innovative to use CAD Technology effectively!