IoT brings endless possibilities for OEMs and establishments to disrupt the fame quo throughout diverse industries with clever products. However, growing IoT answers is a complicated process. An entire product engineering includes hardware engineering, embedded engineering, software program engineering, mechanical layout engineering, and manufacturing. Out of all offerings, mechanical layout offerings dominate.

Today’s customers’ buy selections are particularly inspired by product aesthetics, ease of use, shape factor, and sturdiness to get the preferred product performance. The absence of any of the elements may also result in producing faulty parts, resulting in excessive costs, manpower, and time.

Importance of Product Design Services

Mechanical layout offerings cowl each thing of the product layout procedure including business layout/sketches, 3-D CAD layout, CMF (Colour, Material, and Fitment) layout, 2D drawings, simulation, 3D proto validation, DFM analysis, and drawing update, mold tooling, and very last production. However, it’s far a complicated procedure because it includes growing and optimizing the layout, making sure the business preferred compliance, validating the mechanical layout, and prototyping to supply advanced merchandise.

It meets the aesthetics and mental wishes of the product. Engineering-pushed product layout offerings contribute to becoming durable, tangible merchandise with decreased charges and time to market. It typically satisfies the call for and requirements of customers.

What is Included in Design Engineering Services?

The product style method converts ideas into ended products. it’s categorized into the stages that are as follows:

Industrial Design:

throughout this stage, the commercial designers will flip your ideas into initial sketches to begin visualizing how the product would possibly look. Once you’re happy with the form, they’ll design employing a 3D CAD program corresponding to SolidWorks, Creo, or different tools to make sure the merchandise is possible for each user and therefore the manufacturer. CMF is additionally a part of industrial design wherever designers nail down the color, material, and finish of the product. Designing merchandise with appealing colours, materials, and finishing doesn’t solely serve the purposeful needs however also creates a much better user experience.

3D CAD Design:

3D CAD style is the finished victimization of differing types of 3D software systems to make real-life visualizations of a finished product. By effectively utilizing 3D rendering the designers will augment ancient styles that are functional likewise as esthetical appealing.

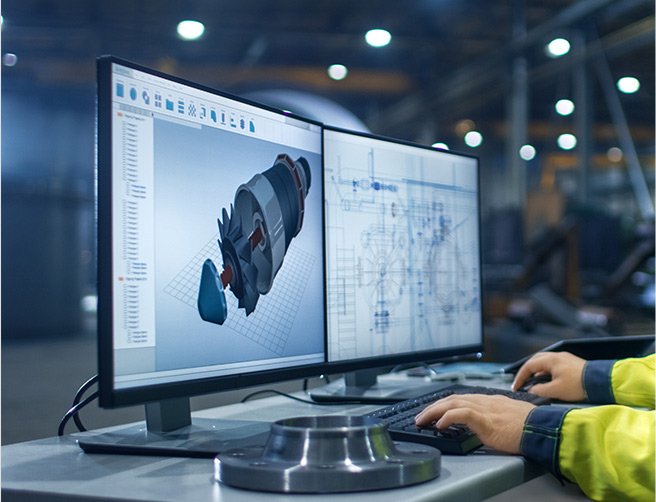

Simulation and Analysis:

Simulation and analysis use advanced procedure methods, design optimization techniques, and visualization tools. for example, using advanced CFD methods, facilitates perceiving the advanced design and performance problems long faced by several original instrumentality makers and enterprises. Simulation and Analysis will be performed victimization ANSYS and binary star tools for thermal analysis, shock, vibration, and drop situations of the merchandise.

3D Written Prototyping:

Prototyping a product can be pricey and slow however using 3D prototyping, you’ll reiterate efficiently. 3D modeling is one of the foremost vital steps of the product style process during this step, you get the thought of the form, fit, and function. 3D printed prototyping is the crucial part and necessary to validate the mechanic and engineering of it.

2D Detailed Drawing

when 3D CAD and 3D written example validation, it’s suggested to create necessary changes within the drawing and needs to unharness elaborated 2D drawings as well as tolerances that are vital to focus on for any process.

Tooling Development

Mechanical engineers can modify any pre-existing CAD from the epitome section to urge preparation for what’s referred to as DFM (design for manufacturing) to ensure the planning is optimized for manufacturable and doesn’t have reserve price embedded in it. supported the projected volume, soft-mould tooling or hard-mould tooling is selected.

Mechanical Style Testing

style validation testing is important to validate a product’s design as per design specifications, meets client requirements, trade standards, and product restrictive compliance. Once the models are created, the mechanical engineering team will validate the design margin by running numerous tests such as shock, drop, vibration testing, and information science xx Testing, to check the merchandise in increasing stress levels of temperature, crash impact, distorted model visualizations, vibrations, the strength of the material, and so forth failure and defects found at this stage are corrected within the modelling section itself. This drastically reduces the scope of any error locomotion up throughout the producing phase.

Production Readiness

Having pre-tested and analyzed CAD Drawings and models helps the manufacturer to initiate the method of defect-free mass production with ease. firms will have trouble-free manufacturing with multiple vendors as per their policy with this type of readiness to upset any uncertainty.

Conclusion

Design engineering is the riding pressure on each product created for customers. Companies that specialize in this area provide value-delivered offerings which are custom designed to the customer’s needs.

Looking for product designing engineering services for your business? Check out Monarch Innovation which is one of the best engineering and design innovation company in India. Contact us for more details.