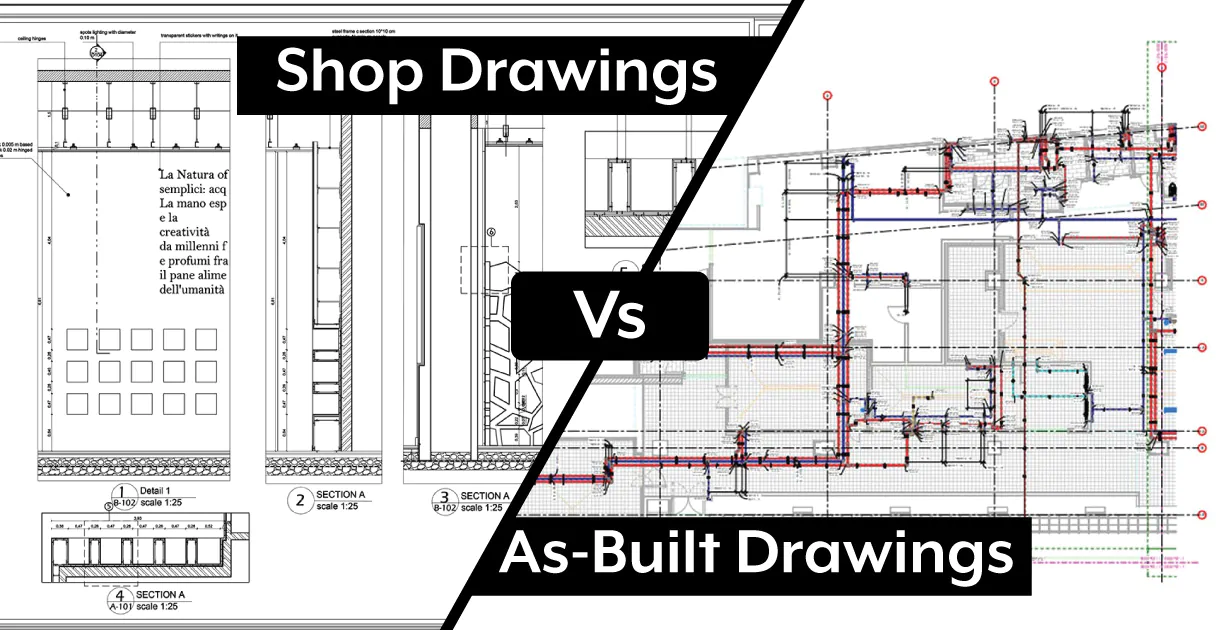

Every construction project needs a design phase to be successfully completed. Each building drawing has a distinct purpose as well as a few elements. A look into various stages of the construction life cycle is given by numerous design drawings. Every building drawing plan must be understood, from the foundation drawings through model creation. You must be familiar with the ideas of shop drawings and as-built drawings if you are from the AEC sector. Let’s examine the principles of shop drawing and as-built drawing and how these two important drawings vary.

What are Shop Drawings?

Every structure is made up of a variety of parts with unique measurements and characteristics. The complete elements—architectural, structural, and mechanical shop drawings—help in determining how they will fit with the entire building structure. The shop drawings are also made before a construction project starts. Shop drawings (also known as fabrication drawings)

The shop drawings are crucial for giving a construction project its authentic personality. The construction crew must agree to and approve the designs, which are crucial for coordination. The shop drawings describe how the project is being built once the design drawings have been authorized.

Specifications of a Shop Drawing

This denotes that all specifications for the architectural, structural, and MEP services will be retained in advance by the builders, contractors, employees, and supervisors. They are a close match to the contractors’ original building design drawings.

Importance and Benefits of Shop Drawings

The construction process’s kind of material requirements are identified by the initial design plan. The creation of architectural, structural, and MEP drawings eliminates the need to waste time or money on training team members on the entire construction process.

All these shop drawings, including those for structural, mechanical, and architectural engineering, are self-explanatory and aid contractors in understanding the dimensions, materials, schedules, installation procedures, and other specifics. Therefore, the initial plan must be set up before the construction process begins.

What are As-Built Drawings?

What is As-Built Drawing, a question that is frequently posed by a lot of people? After the project is finished, architectural, structural, and MEP as-built drawings are produced. They show how the building’s many architectural, structural, and MEP services were put together on paper. To compare the initial plan and the improvements that could have been made as the project neared completion, many MEP sets of as-builts are required. The updated set of as-built drawings can be used to distinguish between pre and post-construction. Many of the mechanical engineering drawings needed for project implementation are also created by contractors. Once the project is finished, the clients receive the set of as-built drawings. They still have all the installation-related structural elements.

Why do you need As-Built Drawings?

From the client’s point of view, all as-built drawings for HVAC and other services are important and aid in their analysis of the finished product. Constructed drawings for HVAC services have a few advantages. They assist in setting up emergency services in a structure. As-built drawings are also essential for carrying out renovations inside the building. The as-built plans, which include comprehensive details on the entire building structure, are referred to as shop drawings once the building has been constructed. This building drawing plan aids in creating backup plans and outlining the emergency evacuation routes in addition to the peripherals for the maintenance team’s future use.

Difference between Shop Drawings and As-Built Drawings

Let’s compare the various construction technologies. Since the contractors produced both design drawings, it is irrelevant when they disagree.

Shop Drawings |

As-Built Drawings |

When are these drawings required? |

|

| There are various shop drawings kinds used in building projects, including MEP drawings, spool drawings, architectural drawings, structural steel detail drawings, etc. Throughout the lifecycle of a building, they alter. | The first detailed design drawings prior to the start of construction are included in the revised set of drawings. As-built drawings serve as a permanent record of any modifications made to the project over its lifetime. |

What is the drawing scope of these drawings? |

|

| Instead of separate mechanical, electrical, and plumbing drawings that are integrated into MEP plans for clash coordination, shop drawings are created for just a few building components. | Precision modules are used to create as-built drawings for the whole build. |

How are the drawings subject to alteration? |

|

| Shop drawings could be modified when the design is still in its early stages. | Since the buildings have already been built, the as-built drawings cannot be changed. They may, however, be changed while the renovation work is being done, and the final assembled drawing created by an architect is referred to as a record drawing. |

In which projects are the drawings required? |

|

| Regardless of the size or type of the project, shop drawings are necessary. | As built are more significant for commercial and high-scale projects. As-built drawings are created by the contractors and sub-contractors starting from the red-lined drafts and constitute an indispensable part of your construction project |

Why hire Monarch Innovation for Construction Design Drawings?

1) Offering safety-related insights

It is simple to carry out process hazard assessments and safety management using as-built drawing designs. The location of equipment shut-off valves is shown on the building set of plans, so you might create emergency evacuation plans, upgrade safety measures, and set up backup plans for the area around the facility.

2) Making future renovations easier

As-built drawings are useful for any future maintenance work of architectural, structural, mechanical, and HVAC services because they solely take into account the final erected structure and installed components. They make it easier to create shop drawings and construction documentation for remodeling older buildings and guarantee that retrofits are carried out effectively.

3) Structure upkeep and operations

As-built plans, which include a clear recorded history of the construction, make it easier to maintain the operation of buildings. They include as-built electrical, mechanical, and plumbing schematics, enabling the maintenance team to complete repairs more quickly through easy reference. Installation, locating, and repairing components becomes challenging without custom as-built drawings.

Conclusion

Get a collection of design drawings that are incredibly exact to enhance your settings. If the basis is precise and clear, visualization can be reflected. Discover the engineering design services offered by Monarch Innovation for MEP, architecture, 3D laser scanning, and structure for rehabilitation or new building projects. To discuss the services for architectural, structural, and mechanical shop drawings, contact our expert.