To understand the difference between BIM and CAD files you must know the concepts of BIM and CAD files and what are their uses.

CAD stands for Computer-aided design whereas BIM stands for Building Information modeling. Computer-aided design programs are used by engineers to assist with the creation, modification, analysis, or optimization of designs with the use of computer systems such as TinkerCAD, Autodesk’s AutoCAD, etc.

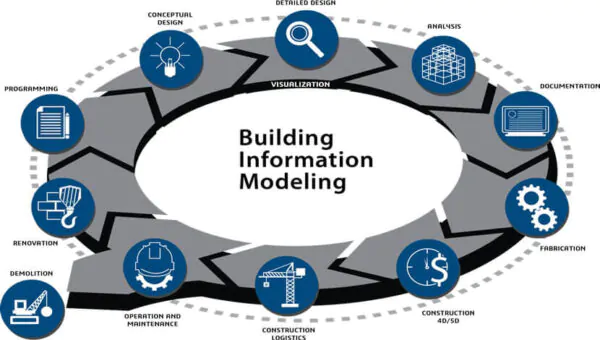

BIM is an acronym for Building Information Modeling. BIM is a new-age process used by architects, engineers, and construction professionals to design and construct buildings and infrastructure more efficiently.

CAD and BIM files have different uses and differ in many ways. You cannot replace one with another. To know the difference let’s understand the concepts in details.

What is CAD and who uses CAD?

CAD is a highly decorative program that is used in the creation of making 2D drawings and 3D models using computer systems. The 3D AutoCAD CS software has been used by these engineers for decades helping them to design and manufacture complex products efficiently and effectively saving a lot of time.

CAD was developed back in 1963 by Ivan Sutherland that broke new ground records in 2D and 3D modeling and visual simulation. Engineers could directly draw on a CRT with the use of a light pen.

CAD programs are widely used by engineers in civil engineering and plant design in various industrial and manufacturing companies. These widely used computer software programs can help you explore and design ideas through photorealistic renderings and simulate how a design performs in the real world

Advantages of CAD

- Easy to use, edit designs and modify drawings using computer-aided software

- CAD models offers improved accuracy over manual drawings.

- When a certain part or aspect of the drawing is required, duplication of labour is removed as everything is available and reproducible digitally

- CAD software has a paper trail to refer back to automatically for any digital design you make

Disadvantages of CAD

- May cause complacency as designers slip into the same design from their library each time and cause your designs to look the same

- CAD allows different aspects of design to be put together but leaves out the bigger picture and the real-world issues of the design when doing so

What is BIM and who uses BIM?

BIM is an advanced 3D model-based program mainly used by architects, engineers, and contractors to design and build commercial buildings and infrastructure. With the help of BIM files, you can analyze and evaluate design decisions before starting the project.

BIM works as a single communication channel between work process and technology to work on the project collaboratively and efficiently. BIM is a digital 3D model based representation and shared resource that can be used by multiple parties involved in the design and build the structure from the beginning till the end.

This 3D model-based representation makes itself a cost-efficient and time-saving process and the chances of making errors are minimal and if any, that can be discovered at an early stage. BIM model provides data that can span the operation and management aspect of the construction project, and this information is later available to the structure owners as well.

Nowadays BIM is being commonly used by manufacturing engineers and contractors to provide a piece of detailed product information in different BIM formats. BIM software tools (the most common one being Revit) have redefined the design and construction workforce amongst the architectural and engineering design firms as well as contractors.

To know more about BIM modeling and using BIM solutions to make your construction project efficiently smoother, reach out to us at Monarch Innovation.

Advantages of BIM

- Teamwork is enhanced as communication across all construction phases and techniques is coordinated

- Any change made to the design either individually or simultaneously by different team members is dynamically shown and monitored

- Even at the planning stage, the final structure or its components can be visualised

- Any clashes between different sets of data in regards to components or between contractors can be identified and sorted before any cost is incurred in reversing the change.

Disadvantages of BIM

- BIM software requires initial software investment and powerful PCs for processing

- Staff and engineers need to be trained in BIM to make full utilisation of its features across projects

- Although it might now sound like a big deal trust and change in work culture is a big issue for various teams working collaboratively on the project to make the most of their data. All parties need to be willing to share the data and invest in understanding its importance

- The client often has no idea of the superior features of BIM modelling and don’t utilise the information presented by BIM to the full extent, wasting the time and effort of the construction team

CAD usage and How Does It Compare To BIM?

CAD models have been useful for a long time to help the architect to understand and render the modifications, development and optimization of the entire construction process. CAD has replaced manual drafting and helped the engineers, architects, and construction managers in creating designs in either 2D or 3D models so that they can visualize the construction of the project.

With the help of CAD now it is easier to make more accurate representations and modify them to improve design quality. It also helps the subcontractors to add up more details to the model.

Nowadays you can create a backup of your drawings and plans in the cloud storage which can be easily accessible by the contractors to CAD-based drawings/plans at the worksite making plan out the modifications easily. It also helps to identify the possible impact the changes might have on construction and adapt as needed and improves communication. This ultimately increases productivity and the effective utilisation of information.

Designers can now create more comprehensive designs considering other elements like electricity, plumbing, structure etc. which has only been possible with the help of CAD. This ultimately enables fewer work changes and a reduction in errors. The technological impact of CAD has been a game-changer in the industrial markets transforming construction into a technology job.

Many Engineers and contractors have been anticipating that these new-aged BIM software tools will become the focus of every new commercial building projects due to its collaborative process that allows architects, engineers and other constructional professionals to construct or design within a single 3D model.

One of the largest upgrades on BIM software from previous CAD software is that BIM allows work in 5 dimensions – time, cost, length, breadth and width. CAD allows work in only length, breadth and width. One can easily understand how this is a game-changer in the construction industry across project teams.

Today’s architects and engineers rely on BIM software to build and design 3D models of their buildings and infrastructure. The power of visualizing something in 3D gives the design and construction team a pretty accurate estimate of what the final structure should look like as well as the cost estimations along the way.

BIM Vs CAD – Which to Use?

CAD is mainly used for industrial design of mechanical and electrical work such as aeroplanes, mobile phones etc. On the other hand, BIM is used in the design and manufacturing of buildings and infrastructure such as airports, schools, hospitals, etc., and has become the most preferred software in the industrial markets. These files also give you the feature to detect virtual collision and construction-related errors before starting the actual work.

BIM models are designed for flexibility i.e., you can zoom in and zoom out and make a detailed design of your building. CAD is more likely a static, high-detailed component that has only one visual representation. A changeable BIM model will enable the CAD file to be viewable in its original form with full detail up to a definite zoom level.

Converting CAD files to BIM file types can result in blurring of CAD components while adjusting the scale of the model whereas adjusting the scale further can cause the image to discolor, appear as a black splotch, or fade from the screen. Hence CAD files fail to self-correct these adjustments when they are incorporated into BIM files.

CAD to BIM conversion – what are the advantages?

Although CAD has ruled the roost for a long time, it is now time to hand over the throne to Revit BIM models, which offer a far larger set of advantages. A lot of CAD designs are being converted to BIM models for high-rise or large scale construction projects because:

- BIM models are more detailed, provide more options for analysis and deconstruction of the data.

- BIM allows work in 5 dimensions – time, cost, length, breadth, and width. CAD allows work in only length, breadth, and width.

- BIM models are easier to manipulate and use to incorporate new changes and design integrations.

- Revit is a software that is now widely used, making it easier to communicate between stakeholders and project teams.

- BIM models help in scheduling the timeline of the construction stages, estimating the cost, and billing the quantities of each component

- BIM modeling can cover the whole lifecycle of the project – right from the design conceptualization to construction to demolition.

- As all the information is pooled at a common spot and changes can be made dynamically, it dramatically reduces the loss of information across the pipeline, and increases efficiency.

To make your project lifecycle come alive with BIM solutions, reach out to Monarch Innovation and let our professional team of consultants and construction experts handle your challenge.

For more information, contact at info@monovative.com Or Call on +91 9974852647